See All Insights

See All Insights

To achieve sustainability goals, reducing supply chain emissions is critical, but far-reaching risks and complexities hinder action. Six proven levers can accelerate progress to decarbonize supply chains.

During this decade of action, no company’s action plan is complete without a cold hard look at how to remove greenhouse gas (GHG) emissions from its supply chain. Despite recent months of widespread, pandemic-driven disruptions to supply chains, corporations continue to ratchet up sustainability targets. In June 2020, corporate Science Based Targets (SBT) hit a record high, up 136% from those at the same point in 2019 (Bloomberg New Energy Finance). Microsoft, Bayer, and Walmart are among the growing list of companies setting supplier emissions targets and taking on the notoriously challenging area of Scope 3 emissions.

Purchased goods and services is a critical Scope 3 emissions category. Global supply chains are complex, opaque, and constantly shifting, so it’s not surprising that these emissions remain massively underreported (see Exhibit A below) and difficult to measure. However, we cannot wait for perfect information before we act. To achieve ambitious decarbonization goals, companies must move quickly to significantly reduce emissions all along supply chains. Efforts that make a meaningful impact must be prioritized over symbolic ones, and these efforts need to be shared, replicated, and scaled.

Thanks to the paths forged by corporate pioneers, there is a well-established toolkit to reduce supply chain emissions. This article explores six proven levers to decarbonize supply chains that procurement and sustainability leaders can implement now.

Stay current on our latest insights. Subscribe for updates →

Organizations often lack the right information to effectively reduce carbon emissions across their global supply chain. In our decades of experience working with a myriad of multinational companies, we've seen the most significant decarbonization potential derived from six key levers. Each lever explores the viability of supply chain decarbonization projects and presents valuable lessons from industry leaders.

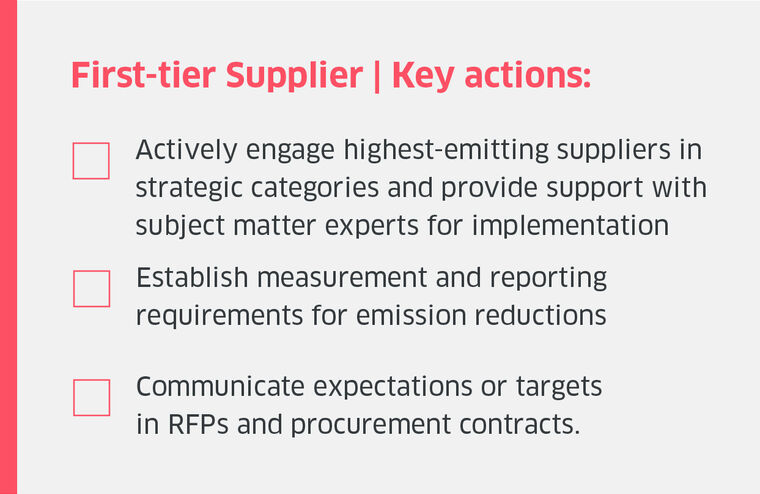

Projects to reduce emissions of first-tier suppliers take different forms: increasing sustainable agricultural practices, switching to lower carbon materials or technologies, designing circular business models, or investing in R&D to improve processes. These projects can be encouraged or required by a buying company or can be developed by a supplier or group of suppliers without any buyer intervention.

Buying companies can start by identifying hotspots: strategic suppliers and categories that are responsible for a large percentage of their Scope 3 carbon emissions. Subsequently, following this strategic buyer-led approach to project development, companies must establish direct engagement with suppliers, preferred relationships, requirements in negotiations, and reporting requirements. When projects are supplier-led, companies can organize into multi-stakeholder coalitions to jointly identify projects and facilitate their implementation. Supplier workshops, trainings and information portals are ideal platforms to foster awareness and share best practices. Collaboration is paramount in empowering suppliers to identify viable emission reduction opportunities and lead project implementation.

How are companies matching action to ambition?

This is arguably the most critical lever that any company has to reduce emissions in its supply chain. While companies can make blanket requirements about emissions reductions for the bulk of their supplier partners, honing in on where the most necessary reductions are and encouraging - or even financing - projects that reduce emissions is the best way to be able to see and measure reductions. Strategic suppliers or suppliers in strategic categories are more likely to be willing to develop projects to meet a buyer’s requirements.

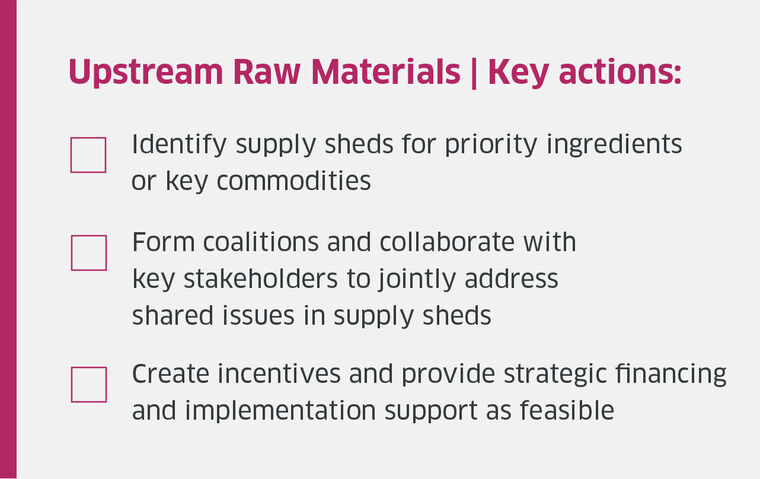

These projects encompass sustainable agriculture, forestry projects, and other interventions that reduce emissions and can drive other positive impacts (eg: biodiversity and sustainable livelihood benefit).

Projects are undertaken within a supply shed (specific supplier geography) in a company's upstream supply chain for a critical raw material. Companies have the option to buy these critical resources directly, and may include community projects where relevant.

As a first step, companies assess risks and opportunities across the upstream supply chain to identify priority ingredients or critical commodities. These projects require a good deal of collaboration with key stakeholders like buyers, suppliers, NGOs, and community stakeholders. Together, they can form coalitions that jointly identify high-impact emissions reduction projects and even jointly fund them. By partnering, companies can unlock shared value at a lower cost or more massive scale. In these situations, coalition members must carefully evaluate the impact to ensure fair and correct emissions calculations and attribution of reductions.

This type of approach is on the rise. It is helping companies to find new and tangible ways to scale emissions reductions, biodiversity loss, and tackle deforestation, which has proven incredibly challenging.

Upstream raw materials projects are the darlings of supply chain projects, offering a heady mix of sustainable agriculture and conservation or reforestation, sustainable livelihoods for smallholder farmers, and carbon emissions reductions. Forests absorb and store about 30% of carbon emissions, while it is estimated that 12% of global greenhouse gas emissions derive from deforestation. Agriculture is responsible for 17% of GHGs and an additional 7-14% through land-use changes. Projects to develop better practices in agriculture and protecting forests, when done well, can reduce emissions and address systemic challenges on valuable land to our shared global supply chains.

More companies are exploring and applying the idea of carbon insetting. While there is still no firmly agreed global definition, insetting essentially enables companies to reduce carbon emissions within their supply chain by incentivizing (e.g., through investment or procurement requirement) interventions such as a change in technology or practice that results in a demonstrable reduction in carbon emissions, which can then be accounted for at least partially as an emissions credit in their supply chain. Insetting opportunities can be found among the projects described in levers 1 and 2 above.

Being aware of insetting can influence how projects are selected and how they are monitored, reported, and verified in the medium- to long-term. Two examples of companies applying insetting:

Logistics offers a powerful lever for decarbonization, but the complexity of transport networks and the rapid pace of technological change makes it challenging to drive action. Companies must better understand their logistics profile, analyzing upstream and downstream logistics, business models (e.g., insourced, outsourced, or hybrid), and modes of transit (road, rail, ship, air).

With that foundation, companies can evaluate the impact of implementing innovative solutions, including route optimization, fleet electrification, right-sizing fleets, alternative fuels, and advanced e-mobility that integrates electric vehicles with renewables, storage, and microgrids. These solutions can then be mapped by their impact over near-, medium- and long-term horizons.

To implement these measures at scale, companies should work closely with logistics providers and peers. They can engage direct transport suppliers when setting buyer expectations, procurement decisions, and supplier engagement efforts. Together, they can also tackle areas of transport that remain incredibly challenging to decarbonize, such as airplane and marine shipping fuel. By facilitating partnerships with transport companies, policymakers, technology providers, and suppliers, companies can innovate to unlock collaborative and competitive efforts that drive the needed market change.

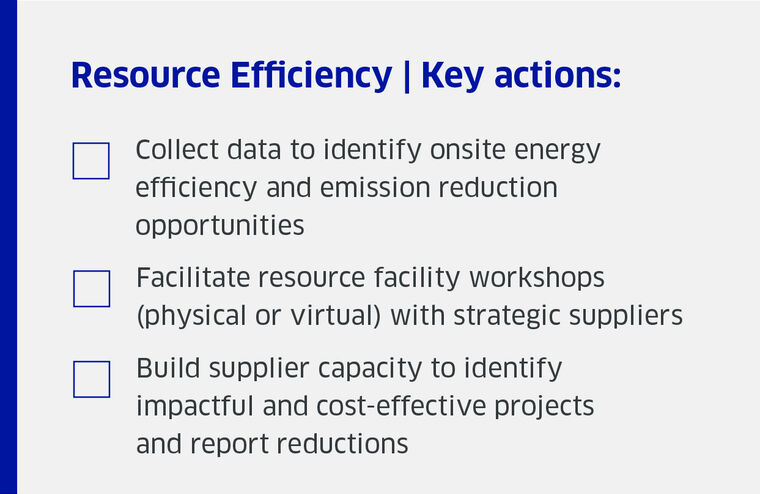

Resource efficiency is low-hanging fruit, mainly when there is manufacturing within a supply chain. Buyers can play a more active role in helping suppliers with manufacturing sites, distribution centers, or other critical physical infrastructure to identify and finance energy efficiency and emissions reductions within their own operations.

To get started, buyers can consider conducting resource efficiency workshops to help build supplier competencies through training and sharing best practices. By engaging resource management experts, corporate and site-level managers can receive hands-on training to quickly identify hotspots, such as locations with significant efficiency opportunities or those with favorable policy or economic environments. By identifying projects with shorter paybacks and clear cost savings, these programs can be entirely self-funding, requiring no upfront capital from suppliers. Conducting these workshops on a virtual platform can be just as successful and significantly accelerate the speed and scale of both cost savings and emissions reduction.

Energy efficiency is a known driver of global emissions reductions. For example, in the industrials and manufacturing industry producing metals like steel, aluminum, and copper from recycled scrap is 60-90% less energy-intensive than primary production using metal ores. It is relatively easy to encourage suppliers and value chain partners to act and can be the basis for rewarding suppliers.

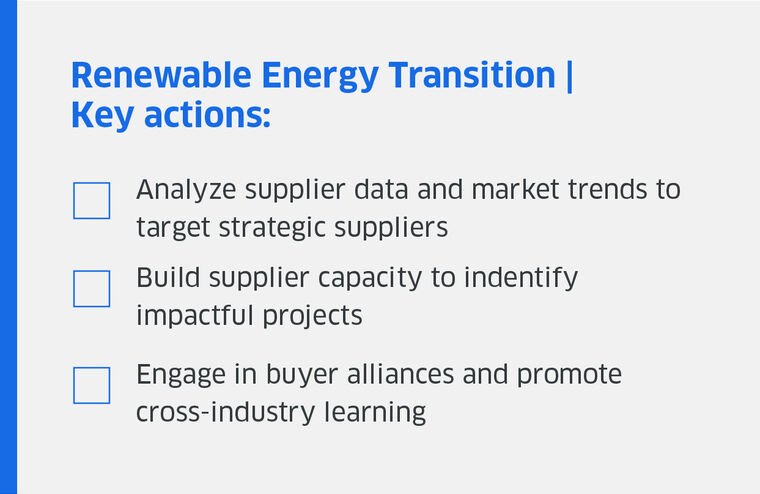

As renewable energy becomes more widespread, companies can demand that supplier’s transition to renewable power. To accelerate decarbonization, they must prioritize strategic supplier sites with the greatest potential for seamless renewable energy transitions. Supplier site targeting is influenced by a plethora of variables, including availability, local policy and market, and type of supplier activity. These factors are most relevant to high energy users like manufacturing and processing sites.

Companies can support implementation by promoting transparency around their renewable energy commitments, setting examples of feasible goals, engaging in buyer alliances like REBA, and advocating for policy change. The overarching goal is to bolster supplier capacity to identify and drive impactful transitions. Buying companies can guide action through direct financing or by coordinating local financing from the government.

Moving to renewable energy is a known opportunity to reduce emissions, but regulatory landscape and availability, plus capital expenditure, can be impediments. By making a concerted effort to understand renewable energy options across its supply chain, a company can help its suppliers overcome lingering barriers.

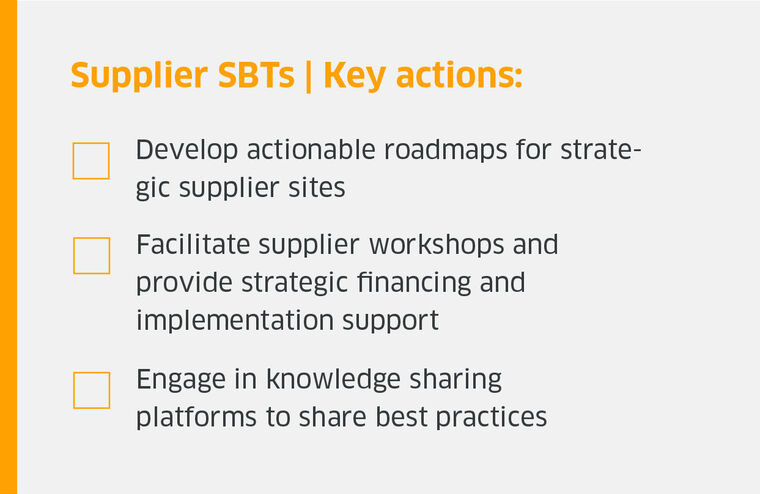

Companies can encourage or require suppliers, usually a sub-set of strategic or critical suppliers, to set Science Based Targets (SBTs).

Target setting is crucial to reduce emissions in line with the scale of reductions required to keep global warming well below 2C degrees from pre-industrial levels. There is significant momentum, with nearly 1,000 companies now committing to SBTs. However, targets do not in their own right reduce emissions. Companies can pave a clear path forward by helping suppliers construct actionable roadmaps to achieve these goals.

Setting SBTs can be costly. Buying companies can amplify their impact by sharing their own expertise through knowledge sharing platforms with other buyers that have set similar targets.

By cascading SBT commitments, companies can drive consistency and accelerate progress. Using the built-in reference point of science-based targets enables companies to assess which suppliers align with their climate ambitions. SBTs also put pressure on a company to deliver quickly, guided by the science, which tells us we only have a short time to address emissions. Given the complexity of setting and achieving SBTs, the value capture of this project is most significant for larger businesses. Ambitious, measurable reduction targets can drive the necessary transformation to not only supplier operations but can unlock substantial growth through transformative shifts to business models, products, and services.

These six ways to decarbonize supply chains can be applied at scale today. A good starting point is to step back, understand where the most significant opportunities are, and ensure alignment with business strategy. Many approaches can be useful, but they need to be wielded wisely across the supply chain as part of a coherent decarbonization strategy, and when they add up, the whole should be greater than the sum of its parts.

So, what are you waiting for? We have a decade. Let’s get to work.

Don’t miss the latest content from our sustainability consultants. Subscribe for our Sustainability Transformation updates.

Let's work together to integrate sustainability across your organization.